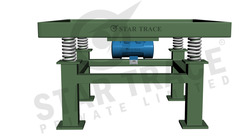

Vibrating tables are designed to settle and compact dry bulk materials in various types of containers. Their application provides either a sizeable increase in the net weight of the container or reducing in the container size with subsequent savings in shipping and storage space.

Vibrating tables are available in two types electromagnetic & electromechanical. The choice of the proper type and model depends upon the application, characteristics of the material or objects being handled, its reaction to vibration, the maximum weight to be handled and the type of container.

| Used for. . . . . .

Fatigue testing

Consolidation of concrete

Foundry shake out

Weighing & filling systems

Foundary mold & core making

Chemical compaction

Frozen food compaction

Portable storage bin compaction

Plastic pellet resin compaction

Homogenising of paint .

| Used in…. .

Electronic indusries

Chemical industries

Pharmaceutical industries

Cement industries

Food processing industries

Foundry

Packaging industries

Paint industries etc. ,

|

Vibrating table, vibrating tables, manufacturer of vibrating tables, manufacturer of vibrating table, supplier of vibrating table,vibrating table in india, exporters of vibrating table, vibrating table manufacturers, vibrating table suppliers, vibrating table exporters, vibrating table manufacturing companies, vibrating table in chennai and vibrating table supplier in india.